- Home

- Products

Precision Gearbox Micro Motor Encoder Accessory

Planetary Gearbox (High Performance)

ZWSMD Φ4mm ZWSMD Φ6mm ZWSMD Φ8mm ZWSMD Φ10mm ZWSMD Φ12mm ZWSMD Φ16mm ZWSMD Φ19mm ZWSMD Φ22mm ZWSMD Φ26mm ZWSMD Φ32mm ZWSMD Φ38mm ZWSMD Φ42mm

Planetary Gearbox (MD Series)

ZWMD Φ3.4mm ZWMD Φ4.3mm ZWMD Φ6mm ZWMD Φ8mm ZWMD Φ10mm ZWMD Φ12mm ZWMD Φ16mm ZWMD Φ20mm ZWMD Φ22mm ZWMD Φ24mm ZWMD Φ28mm ZWMD Φ32mm ZWMD Φ38mm

- Markets

- Company

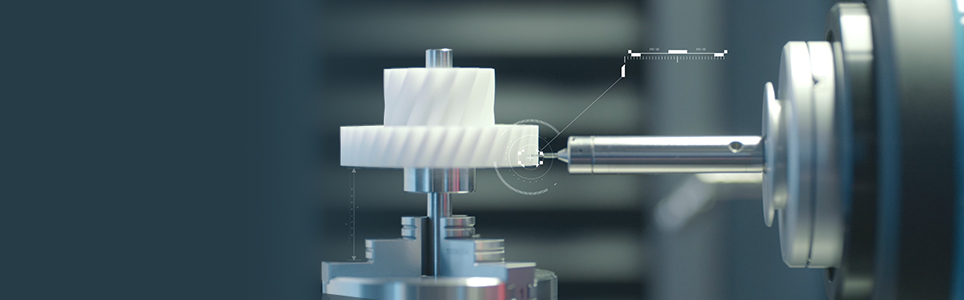

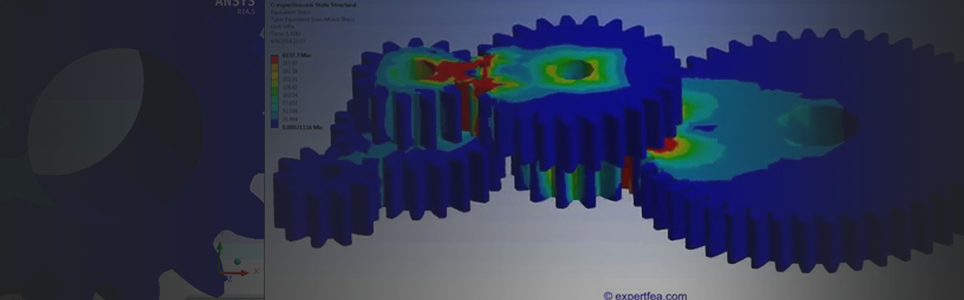

- Technology

- Video

- Contact Us